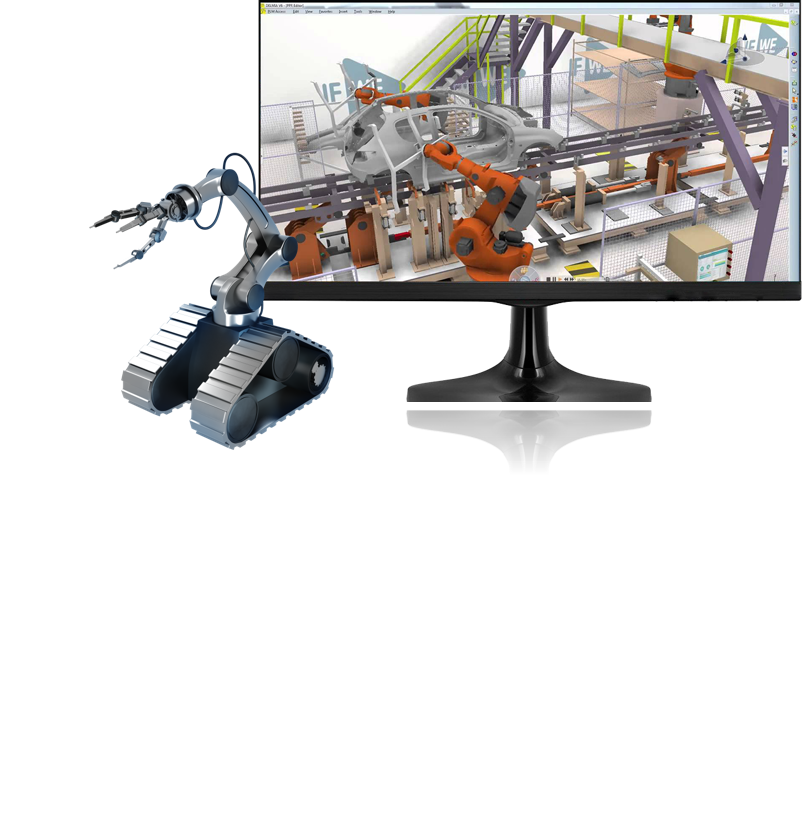

3D virtual production solution

DELMIA provides virtual digital production environments to optimize production system and processes.

It realizes organization and verification of manufacturing processes, production optimization, and maintenance simulation to maximize productivity.

Strong Points

- Provides 3D data-centered collaboration environment

- Open-type architecture

- Manages product, process and resource information

Application

- Automobile, aircraft, shipbuilding, electric/ electronic, machine manufacturing, molding, construction, steel making, clothing, pharmaceutical, consumable, logistics, energy industries, etc

Function

- Reviews prior digital engineering method, process and production in consideration of products, process, resources, and layout in the 3D digital environment

- 3D virtual ergonomics to review safe working environment

- Virtual commissioning to reduce try-out time

- Analyzes the patterns of risk factors to present optimal productivity

Live Process Review ย

Functions

Compatible to read V5 and V6 PPR (Product, Process, Resource)

Replay simulation data produced in V5 and V6

Reviews PPR data

Manufacturing Process and Resource Project Administration for Managers ย

Functions

Manages products, process, and resources

Provides the function to manage projects

Manufactured Product Planning

Functions

Automatically EBOM-based MBOM

Extends MBOM to collaboration environment

Process Planning for All Industries

Functions

Creates and manages process plans in V6 collaboration environment

Automatically creates product structure-based process plans

Able to balance work in Manufacturing System

Able to create work graph with Live System Editor

Reviews process plans in 3D layout environment

Analyzes industrial standards-based working hour (SMT)

Makes mixed-model production plans

Custom Time Analysis ย

Functions

Analyzes time according to customer standards (STM)

Provides editable data cards

Graphic preview of edited data cards

Interactive 3D Assembly Feasibility Studies for Product Designers ย

Functions

Traces automatic assemble/ disassemble paths

Provides 3D manipulators to create parts path

Automatically creates assembly sequences

Interactive replay of assembly sequence and paths

Fastener Planning for All Industries

Functions

Defines fasteners in car body assembly lines

Visualizes fasteners in 3D environment

Automatically selects a welding gun for each fastener

Reviews the availability of a welding gun in welds

Allocates welds to car bodies through assignment assistant and checks non-allocation welds

Define and Simulate Manufacturing Systems ย

Functions

Defines manufacturing systems

Defines assembly flow, buffer capacity and logistics time

Allocates process time to production

Monitors system status in simulation preview

Statistical analysis and reporting of process and equipment capability

Reviews mixed model simulation

Define Factory Resource Layouts

Functions

Defines resource BOM

Uses catalogues to ordinary/ parametric equipment

Allocates equipment on 3D

Extracts dimension and major notes on 2D assembly drawings

Program, Simulate and Validate Mechanical Device Behavior

Functions

Control programming of mechanical devices

Defines work sequences of multiple equipment

Creates and synchronizes in/ out signals of devices

Defines device motion controllers

Program, Simulate and Validate Industrial Robot Behavior ย

Functions

Programming for industrial robot-assisted works

Optimizes robot path and work

Creates robot in/ out signals and synchronizes with other devices

Defines work sequences for multiple robots and devices

Assigns inverse kinematics to robots and devices

Defines motion controller and motion group for robots

Creates grid-based tags

Automatically allocates robots to operational positions

Generate and Manage Robot Spot Welding Programs

Functions

Provides programming tools dedicated to spot welding robots

Provides the function to search welding guns and analyze welds

Analyzes the section of a welding gun by using sectional stack-up

Balances welding work by allocating hitting spots among multiple robots

Updates automatic robot welding program after change of design

Easy editing of welding analysis scenarios

Computer Aided Generation of Robotic Arc Welding Programs

Functions

Provides arc welding-dedicated programming tools

Automatically creates product shape-based welding paths

Easy updating of robot paths according to change of design

Optimizes workpiece locations

Supports Controller-Specific Weld profiles

Creates seam search paths

Remote Assistance

Remote Assistance News

News TeamViewer

TeamViewer Rsupport

Rsupport Facebook

Facebook KOR

KOR